Last night I picked up a gate latch from Home Depot, and it worked perfectly in holding the flip-top table…

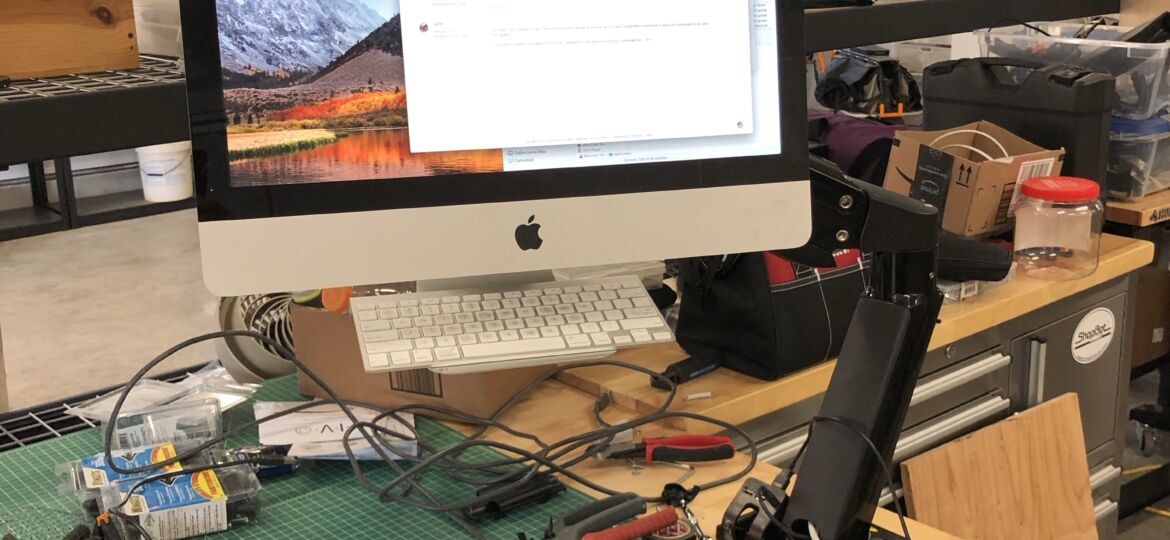

MakerCave Move

I put the FSL Muse Laser Cutter and Engraver to work after the installing the new exhaust vent. Jill want…

Another piece of equipment on wheels While browsing my email, I saw that Woot was offering a mobile tool base,…

I hired one of McKenzie’s classmates, David, to help me move MakerCave. I remember helping my godfather in eighth grade…

I am working on consolidating work surfaces in order to conserve space, and one of these is my vinyl cutting…

You must be logged in to post a comment.