In 2011, I purchased my first 3D printer at the Bay Area Maker Faire, a 3D Systems Rapman, and that…

Shop Log

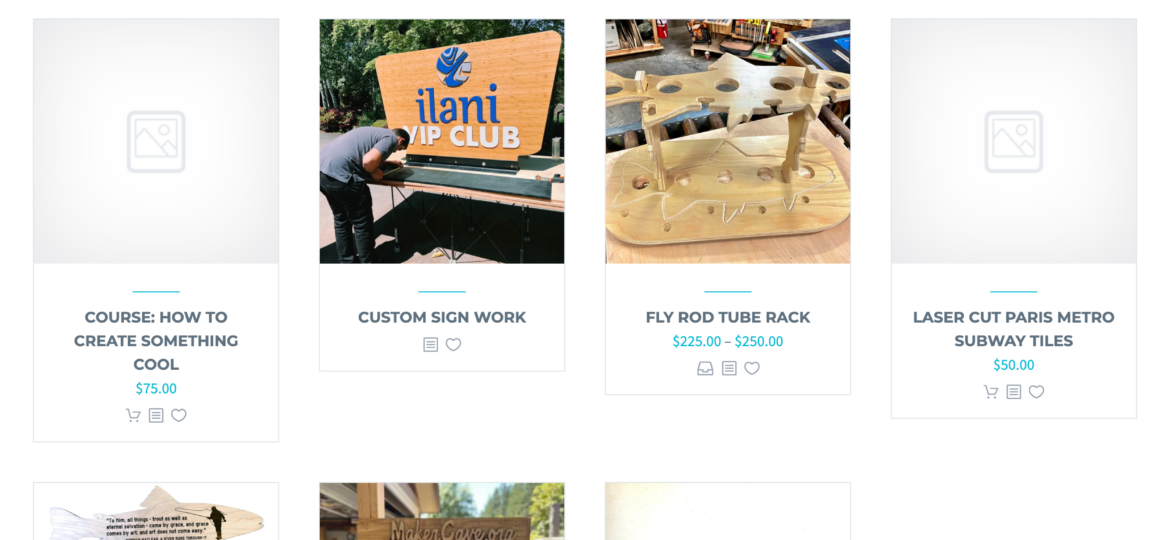

As a maker and creative enthusiast, I’m always on the lookout for new tools and technologies that can help me…

While cutting wood with my DEWALT DWS780 Compound Miter Saw, I noticed chunks of plastic flying off the saw. I…

I realized how long it has been since my last post, how much I have neglected this website. Recognizing that,…

Because of the size of the Big Island, I had to be a bit more creative in getting a piece…

You must be logged in to post a comment.