Because of the size of the Big Island, I had to be a bit more creative in getting a piece…

X-Carve CNC Router

My first attempt to carve the Hawaiian Islands Chain was to have it fit all on the bed of the…

I finished an order for some custom national park signs. In between coats of paint and sealer, I did some…

The latest few days I have been working on designing a LEGO minifig display, and here is my first attempt…

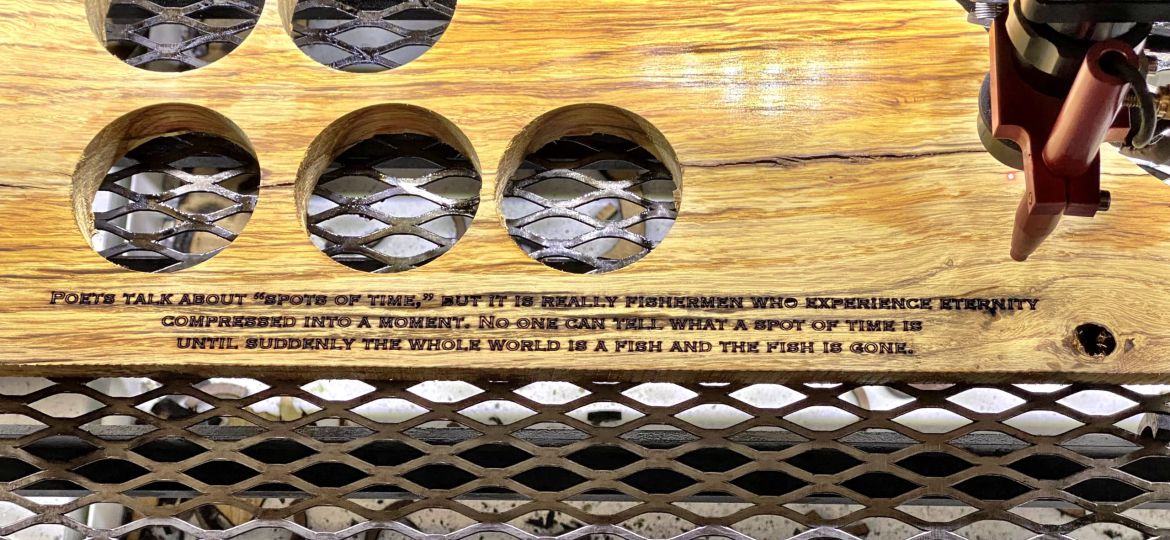

I reused the wheel base for the dust collector, which I no longer needed since I mounted it to the…

You must be logged in to post a comment.