I finished painting the dog silhouettes and names and applied finishing wax to walnut backing boards.

FSL Muse Laser Engraver and Cutter

I continued to cut out dog silhouettes out of 1/4” walnut stock on the FSL Muse: an English Bulldog, Brittany…

In preparation for our trip to Hawaii next week, I created these custom stoppers out of scraps of thin stock…

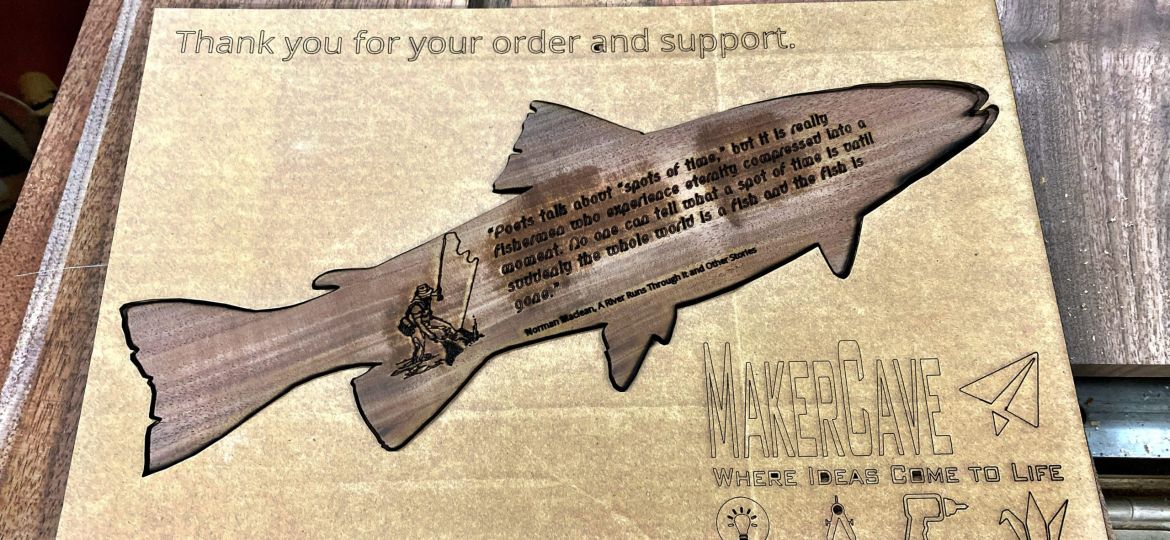

I finally opened my Esty store at https://www.etsy.com/shop/MakerCave, and I received my first order, two Poet’s Quote Trout to Mary…

I was so happy with the thin stock walnut remnants I picked up at Goby Walnut Products that I picked…

You must be logged in to post a comment.