Carts, carts, carts…I continue to get as much as possible on wheels. Today I got the work supports and folding…

2019 November

On Wednesday, I moved my air compressor from old MakerCave to new MakerCave. I attached my air hose and tools…

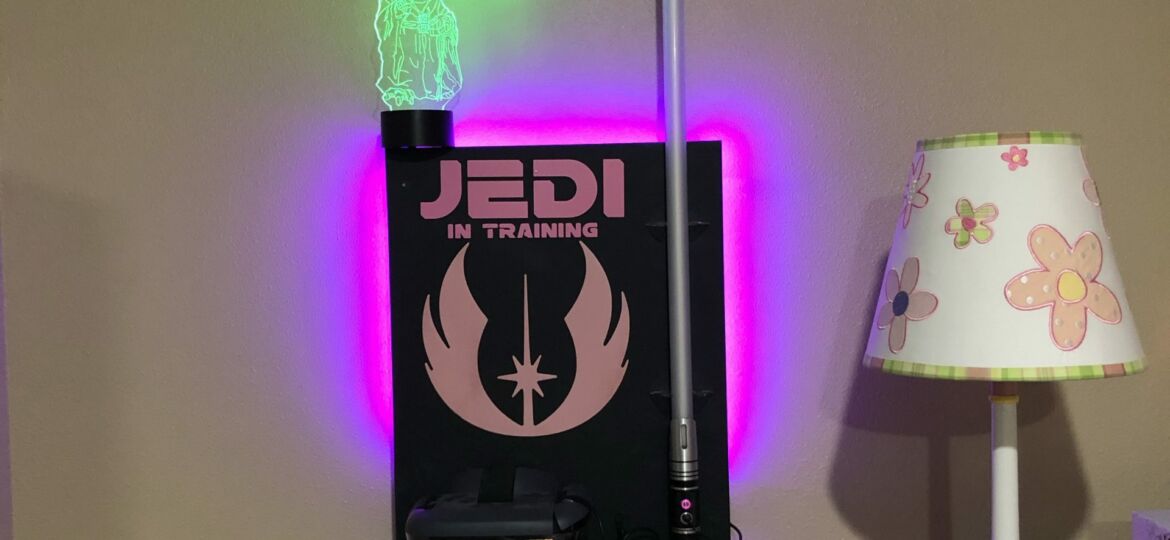

I moved McKenzie’s Jedi shrine from the old bedroom to her new bedroom. During the transport, the plastic brackets I…

The couple of days I have been plugging away at organizing MakerCave: I installed shelving from the garage at the…

Last night I picked up a gate latch from Home Depot, and it worked perfectly in holding the flip-top table…

You must be logged in to post a comment.