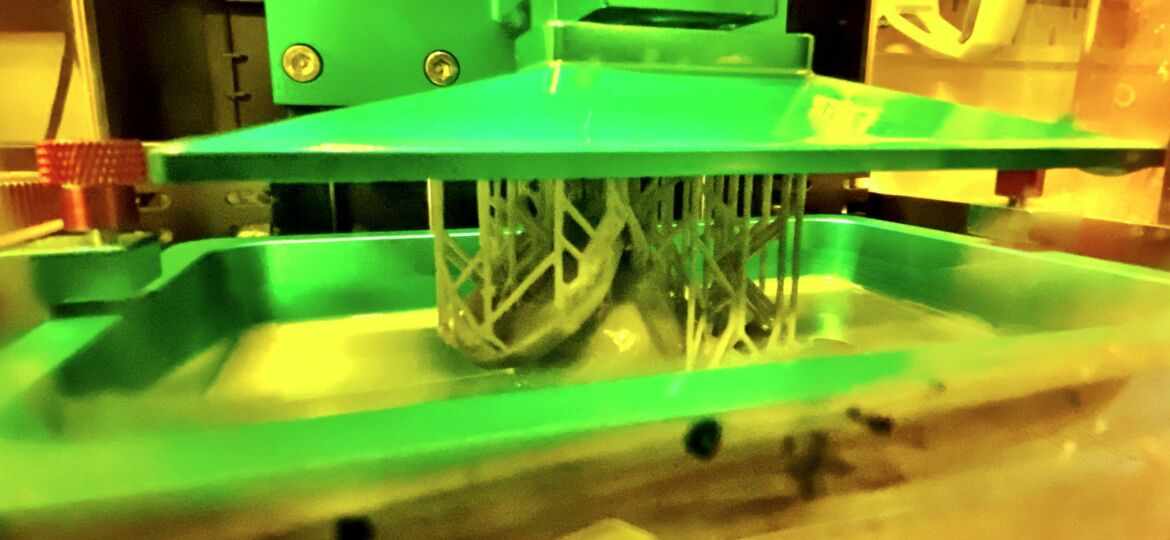

I am having issues with the Anycubic Photon S printer. I ran out of Anycubic green resin and switched over…

GCC Expert24LX Vinyl Cutter

I hired one of McKenzie’s classmates, David, to help me move MakerCave. I remember helping my godfather in eighth grade…

I am working on consolidating work surfaces in order to conserve space, and one of these is my vinyl cutting…

You must be logged in to post a comment.