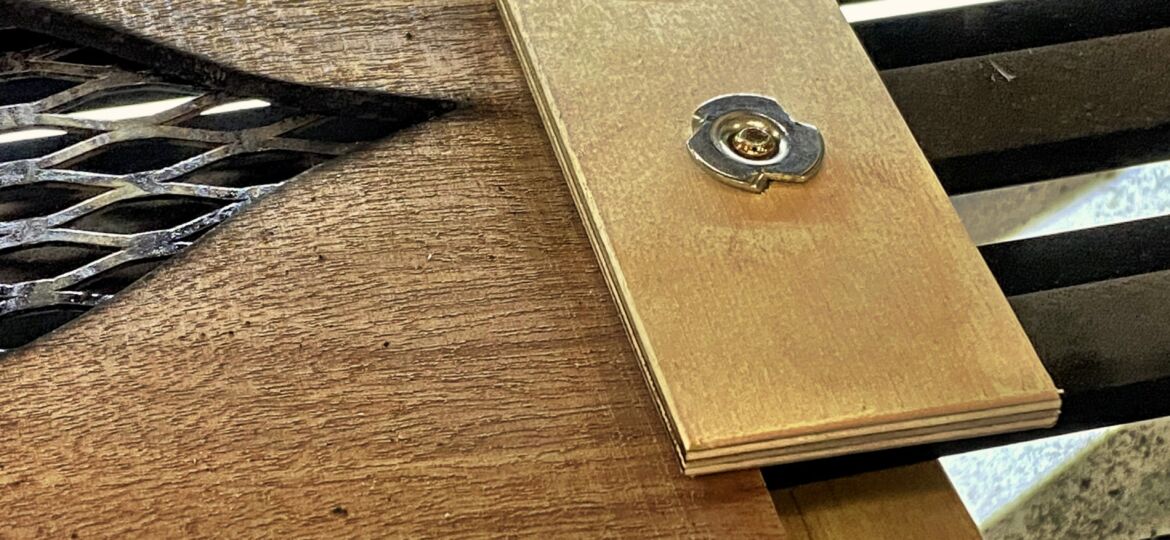

I have been devising a method to hold sheet material flat against the knife bed of the laser cutter. I…

RTJ-1390I Laser Cutter

I began to notice diminishing performance with my RTJ-1390I Laser Cutter and realized that I hadn’t cleaned the mirror and…

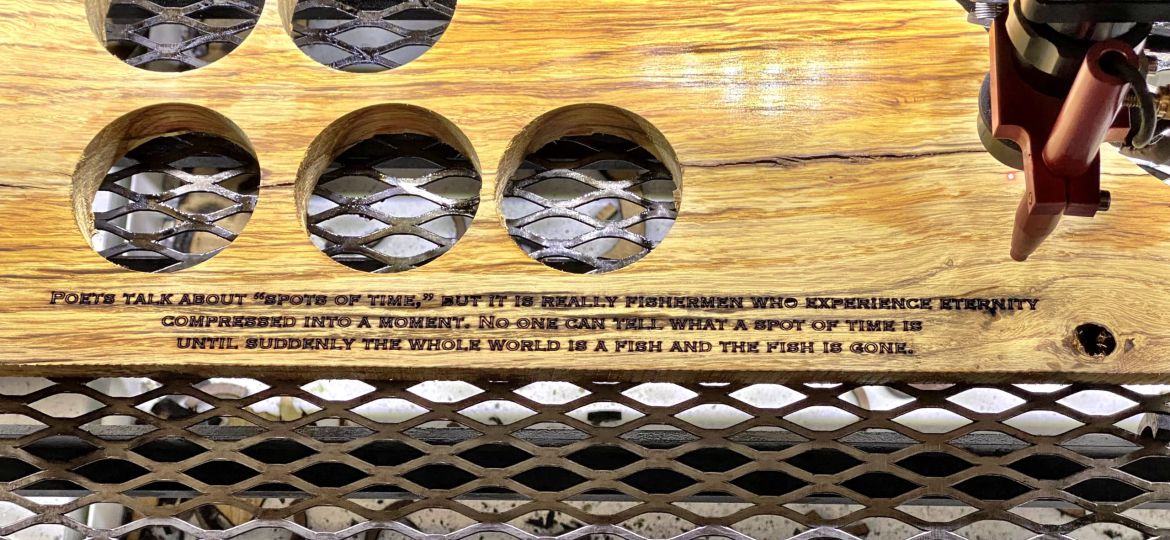

I realized that I was accounting for the kerf of the laser cutter, or the amount of material removed during…

A snow storm hit yesterday, dumping over a foot of snow and some across the area. I grabbed my iPad…

I reused the wheel base for the dust collector, which I no longer needed since I mounted it to the…

You must be logged in to post a comment.