K40 Laser Engraver and Cutter

It has been a while since I have been able to putter in the shop. I worked on aligning the…

I had some fun with the Muse today. I discovered a living hinge generator website and made up a quick…

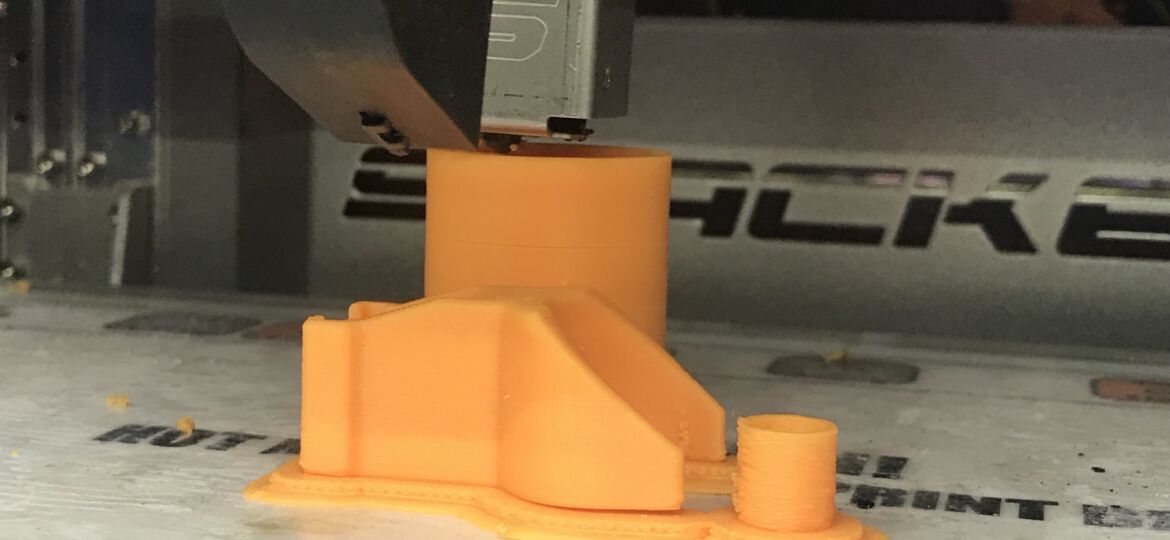

Last night, I sketched up a design for the water flow pressure sensor and then printed it out on the…

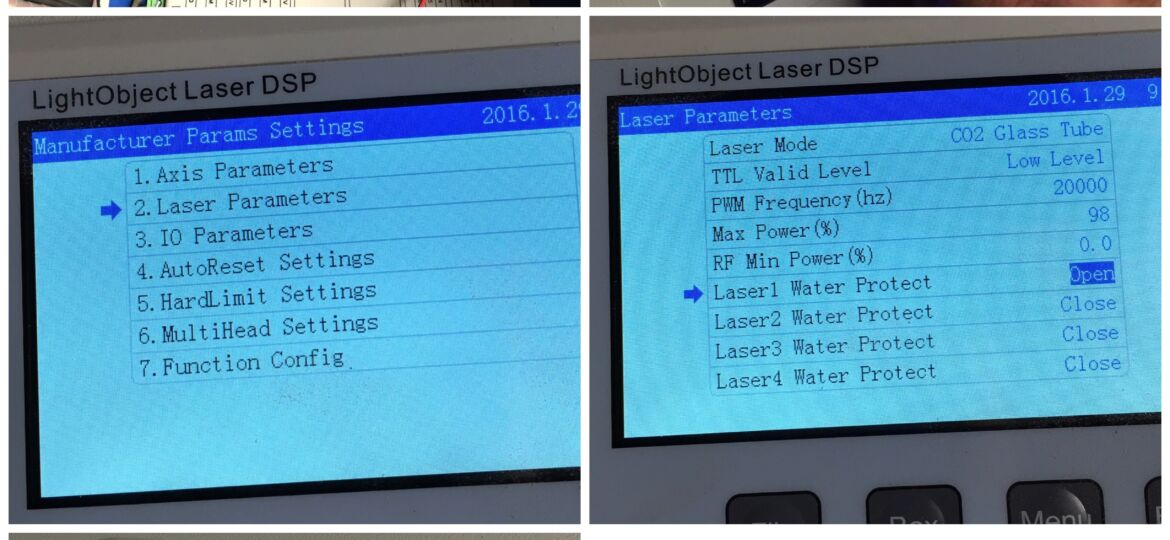

I also verified that the K40 works when the water pump is running. Next create a mount for the water…

You must be logged in to post a comment.