Last night, Jill and I won the fourth grade class auction project, and it is on temporary exhibit at MakerCave….

2016 January

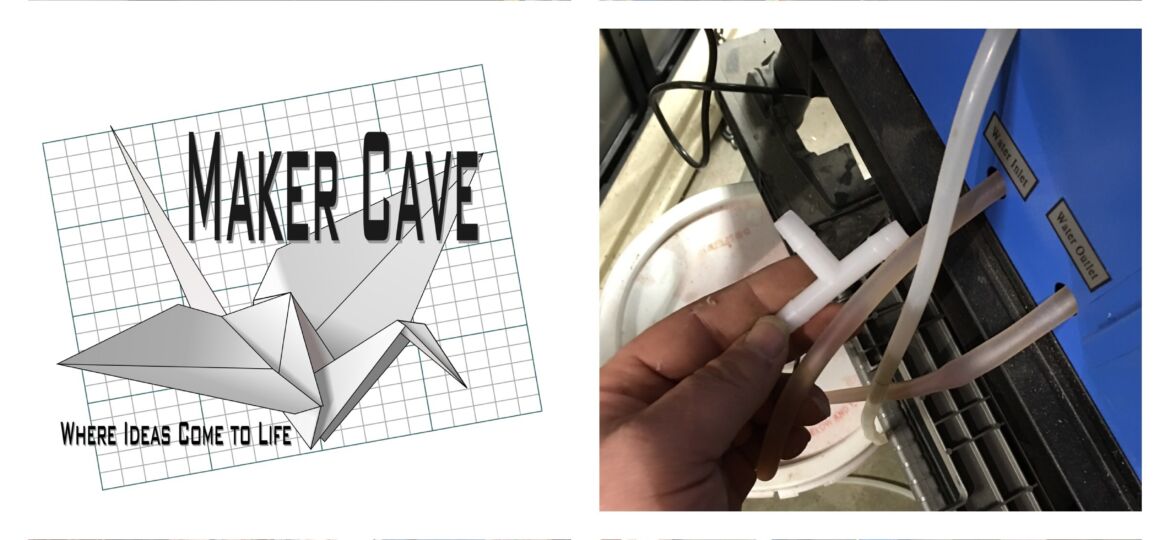

Last night, I sketched up a design for the water flow pressure sensor and then printed it out on the…

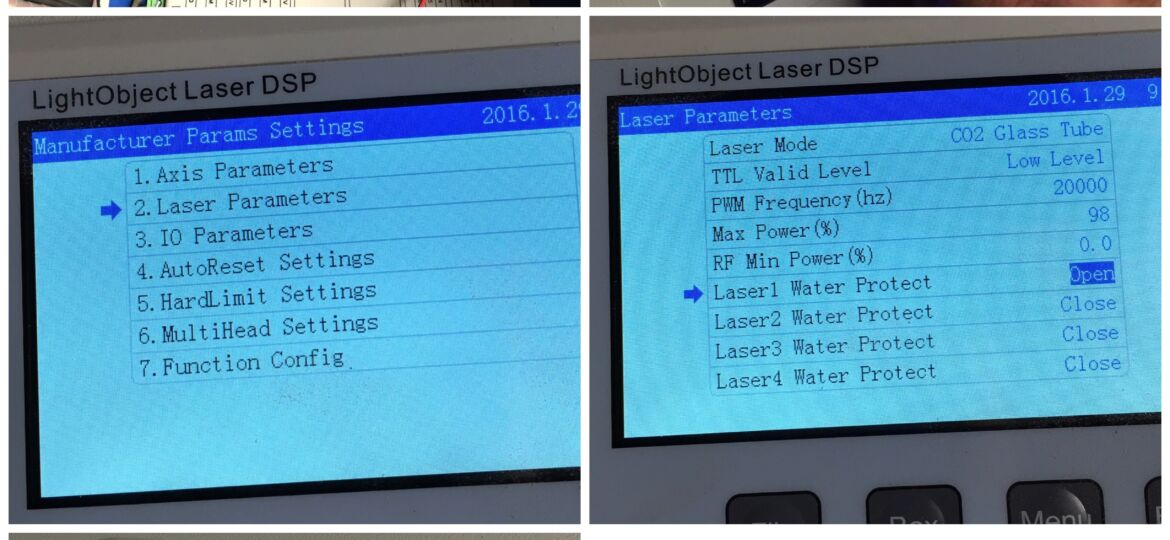

I also verified that the K40 works when the water pump is running. Next create a mount for the water…

You must be logged in to post a comment.